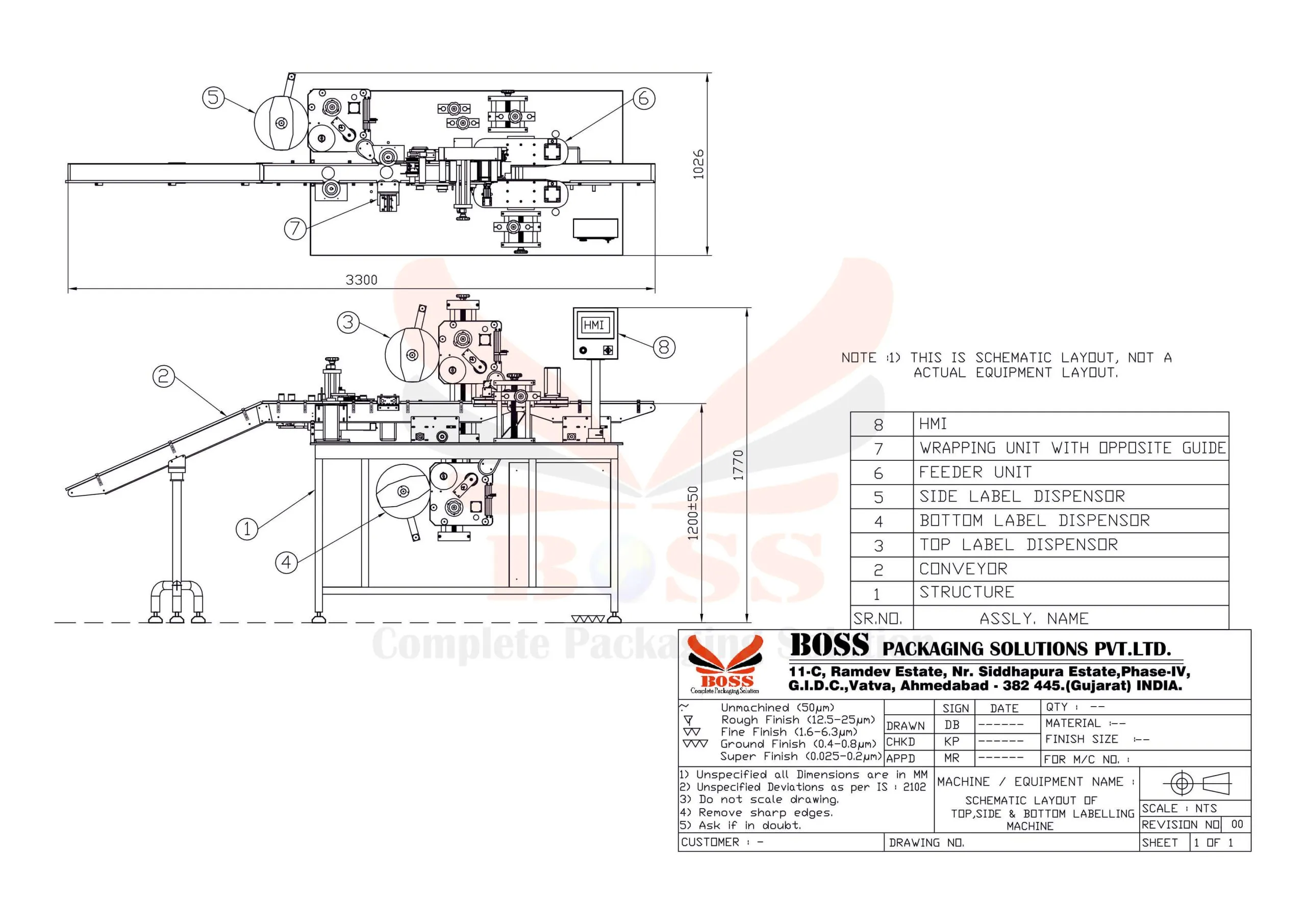

This automatic top and bottom labeller is very user friendly and highly efficient. It is a heavy duty machine which is built using the SS304.The top and bottom labelling machine can label on the top as well as on the bottom surface of the containers at the same time. This versatile top & bottom labelling machine has a speed that ranges from 30 to 80 pieces in a minute, depending on the size of the label and the product.

Moreover, this modern equipment also allows the users to select different speeds for both labelling and the conveyor. It is basically controlled by PLC and Touchscreen HMI so its ensure accurate label Placement and easy control of machine. This automatic machine also incorporates a customized conveyor and Product Feeder. The online label application, independent operation, and the height and angle adjustments through an easy hand wheel, are the other salient features. It also uses the encoder technology to properly synchronize the conveyor with the dispensing system.