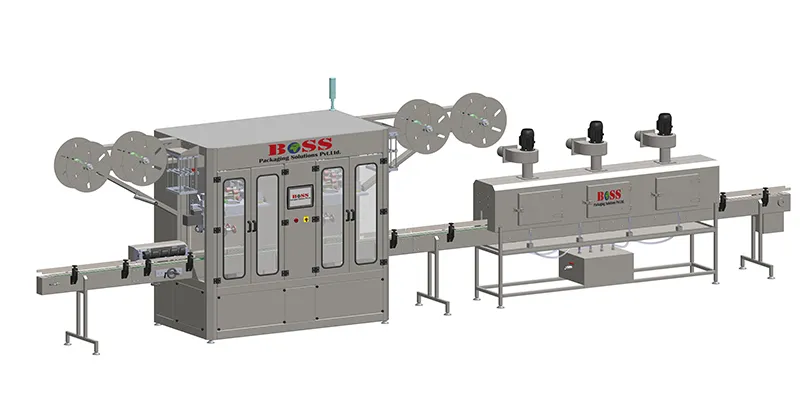

Introduction of Automatic Shrink Sleeve Label Applicator

Automatic shrink sleeve applicator is used in application of the shrink sleeve label onto container. Widely used in foods, beverages, personal care products, cosmetic and pharmaceutical. With the advantages of good flexibility and efficiency. Shrink sleeve applicator can be connected with liquid filling machine, capsule tablet counting line, sleeve shrink wrapping machine and so on to form a complete production line.

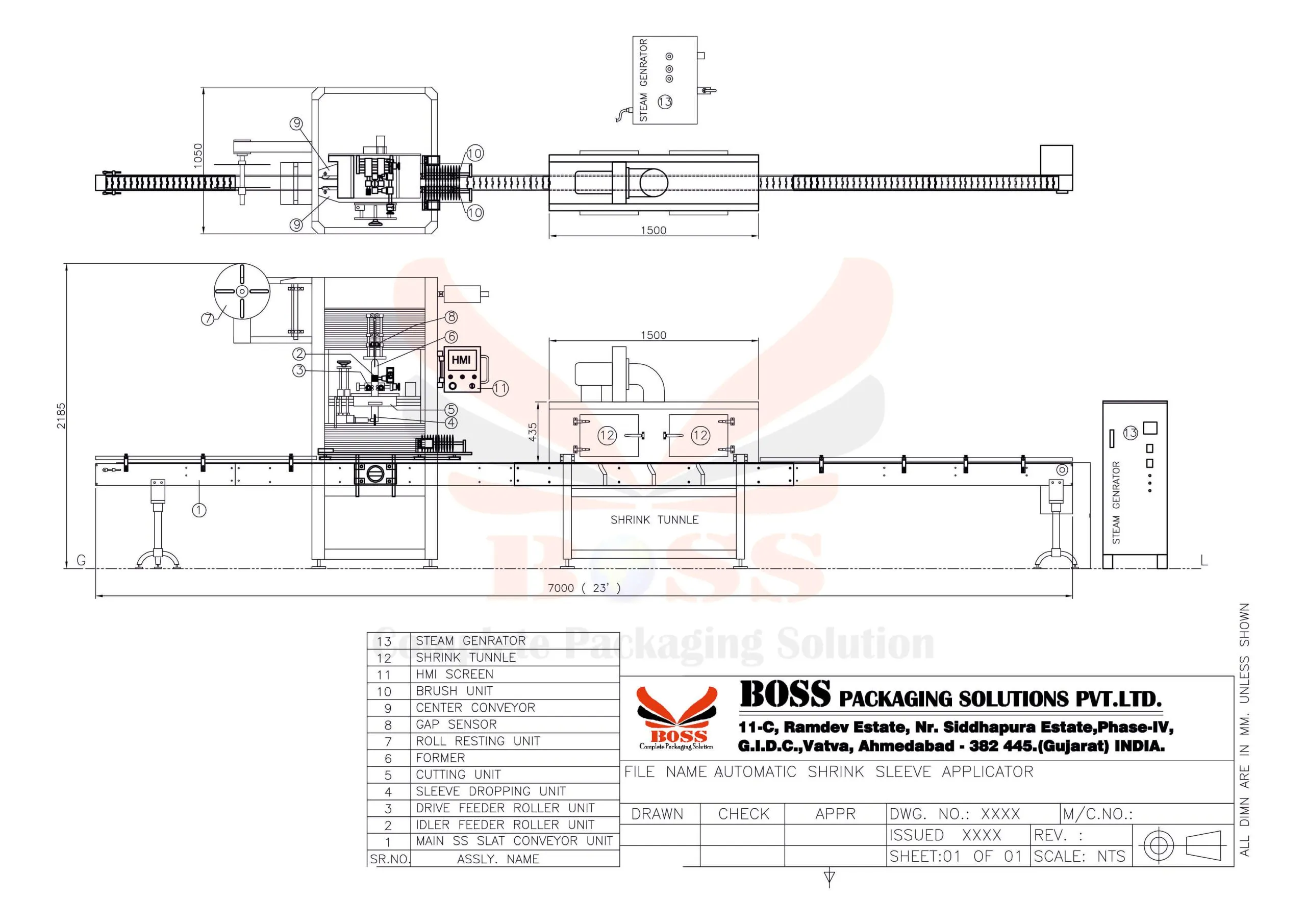

Working Principle of Automatic Shrink Sleeve Label Applicator

The sleeve, supplied in the form of a continuous web with printed graphics, is continuously unrolled from the reel through rollers and it is then put on the forming tube, which opens and prepares the sleeve for the cutting operation. A rotating blades system cuts the sleeve at the required length, which is then positioned and pulled on the product as a label. The product thus obtained is then conveyed into a steam or electric (option) shrinking tunnel, so that the sleeve fits perfectly to the contour of the container.