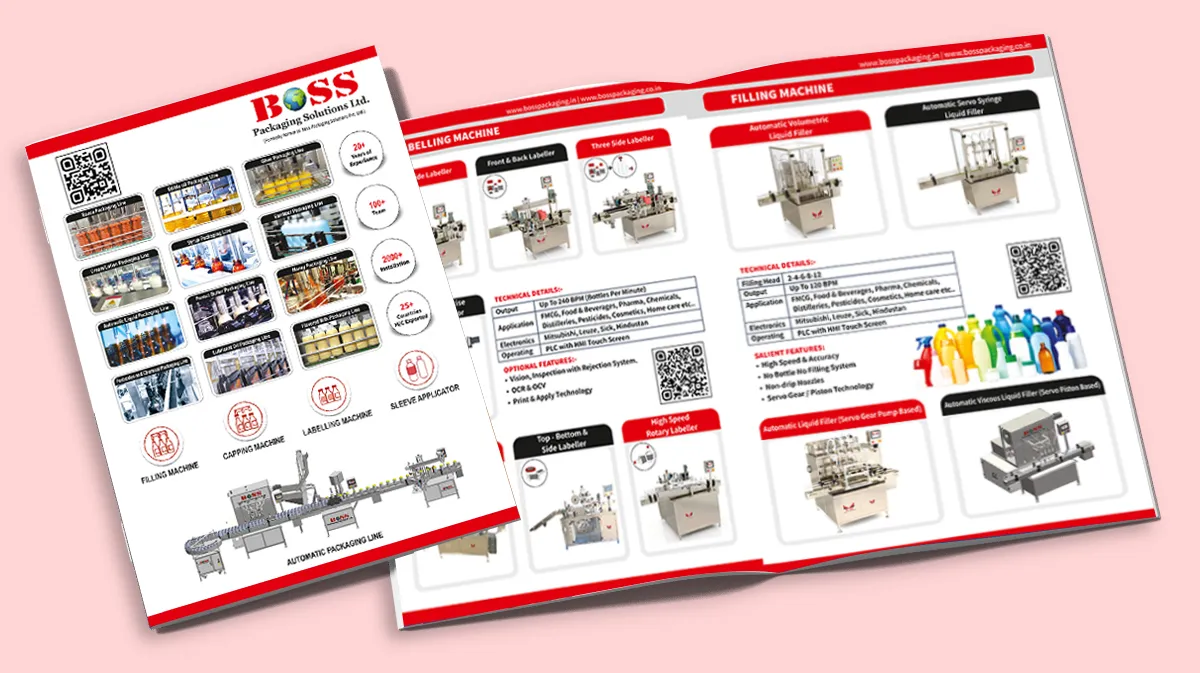

Automatic Labeling Machine Exporter

Automatic BOPP Labeling Machine offered comprise hot melt labeling machines that can be made available by us in different operating model options to choose from. Featuring automatic operations. these can handle bottles of different size capacities as well as in varied production speeds. The use of superior grade stainless steel in construction also makes these machines deliver optimum performance support

These machines find suitability in meeting the Labeling demands of products like bottles, jars, vial, tin and other packaging in round finish form. Further, the presence of microprocessor control based label dispensing system as well as advanced sensing system for label and products also assure of optimum support in involved processes.

The label roll is to be installed on the rotary drum. The label reel is routed through its track to the rotary label cutter assembly through the feed roller. The length of the label is controlled by Trio, with the help of Colour photo-cell, sensing the “I” mark on the label. Then the label length is cut by the label cutter assembly. The label is then transferred to the vacuum drum by air pressure and vacuum system and the label is held firmly at vacuum drum. During the rotation the label takes the hot melt glue from the glue drum on its leading edge and trail in edge. The hot melt glue is transferred by the pump. The bottles are transferred by the In-feed star and positioned to the rotary vacuum drum. The bottle starts rotating, when comes in contact with the drum and the label is rolled on to the bottle against the pressure of roll-on press pad. The bottles are then transferred to the exit of the machine by the conveyor system. All the movements are controlled by electro-pneumatic controls.