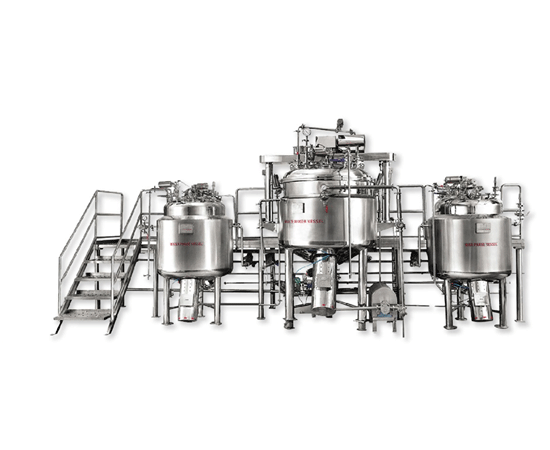

Ointment Manufacturing Plant in India

An Ointment Manufacturing Plants process homogenization of semi solid with liquid components to produce ointments, creams, lotions & gels. There are three different vessels for individual operations connected with each other through pipelines & valves to process as one complete automatic ointment manufacturing plant. The Water phase vessel heats the water, the Wax phase vessel melts the jelly or wax into liquid state and Manufacturing vessel perform blending operations of all the available ingredients. Such Manufacturing Plants are high end systems uses modern technique to enhance production performance. Equipment comes handy in the production of quality products in industries such as pharmaceutical, herbal and cosmetic. Plant offers flexibility to producers and equipped with high class features.