- Home

- About Us

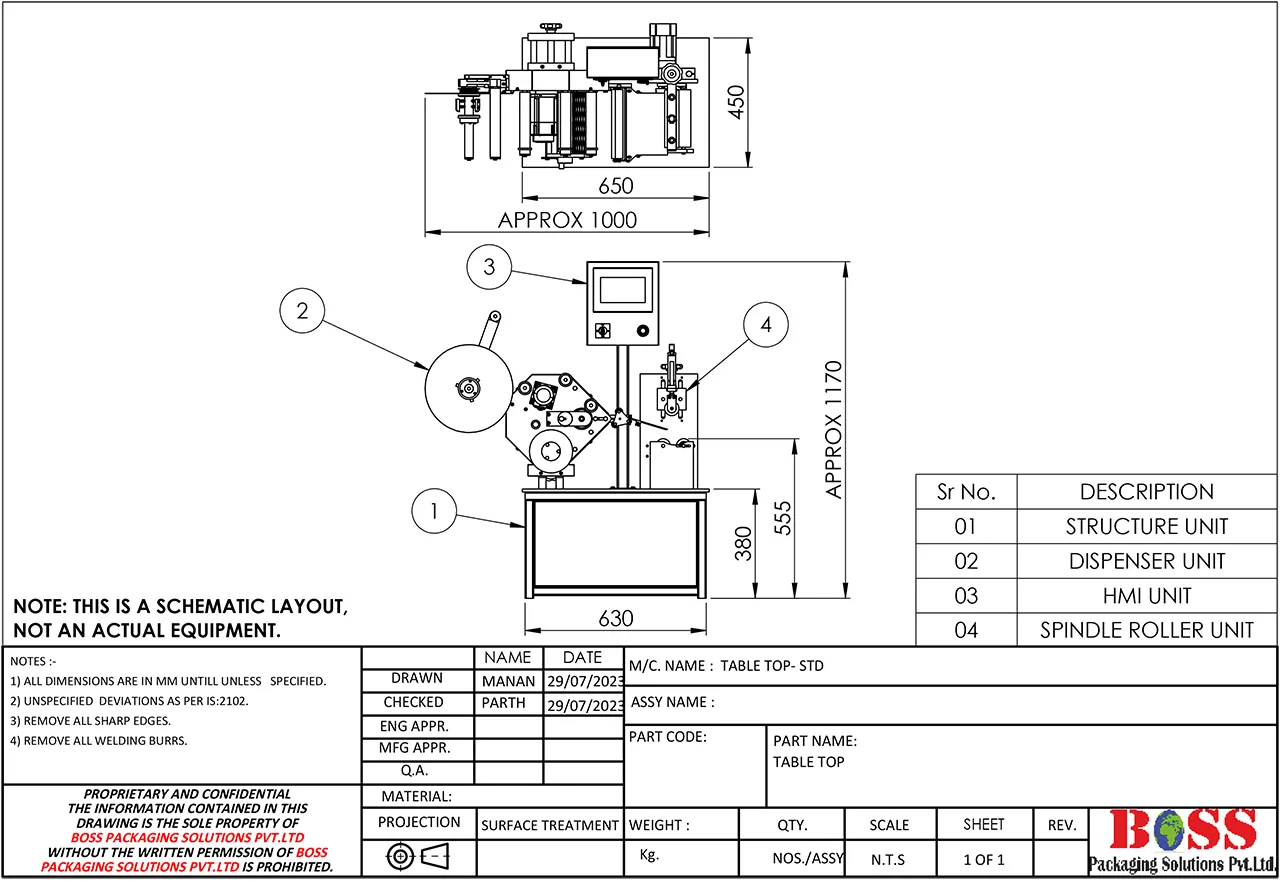

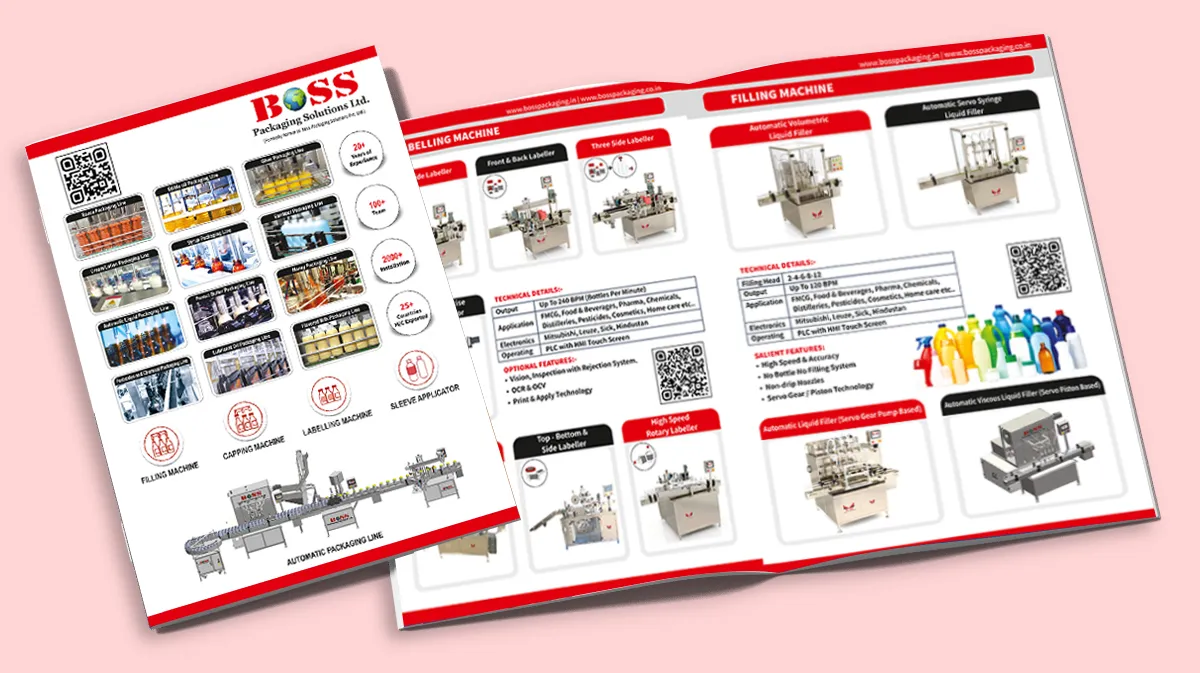

- Product Range

- Video Gallery

- Careers

- Investor

- Company Information

- Board of Directors

- Composition of various Committees of Board of Directors

- Investor Grievance Redressal

- IPO Documents

- Company’s Code & Policies

- Annual Return

- Financial Information

- Material Documents and Agreements

- Shareholding Pattern

- Compliance Certificate Under Regulation

- Corporate Announcement and Other Information

- Events

- Contact Us