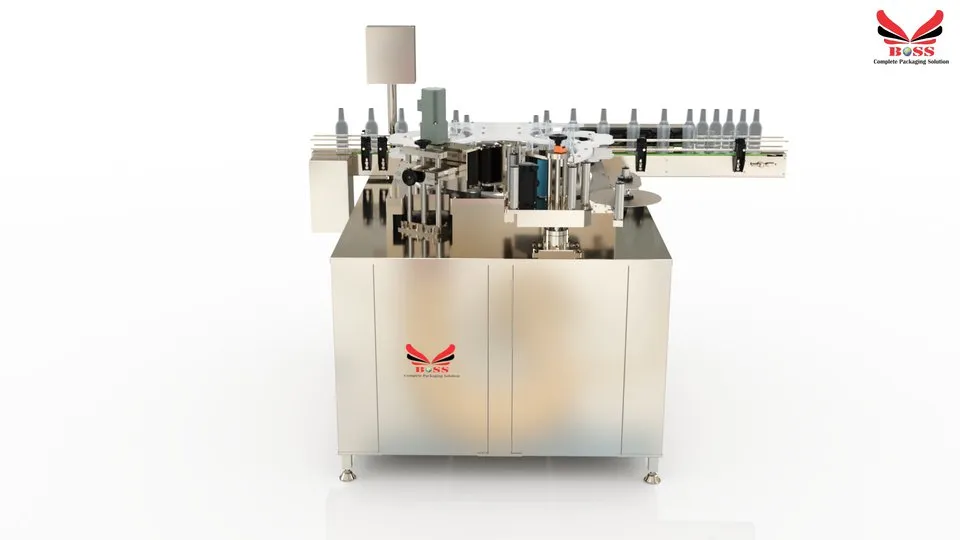

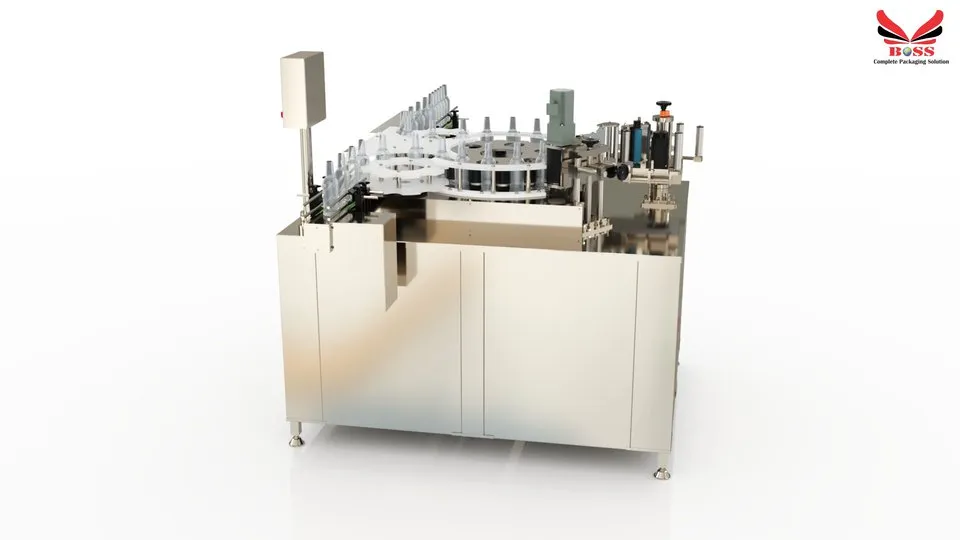

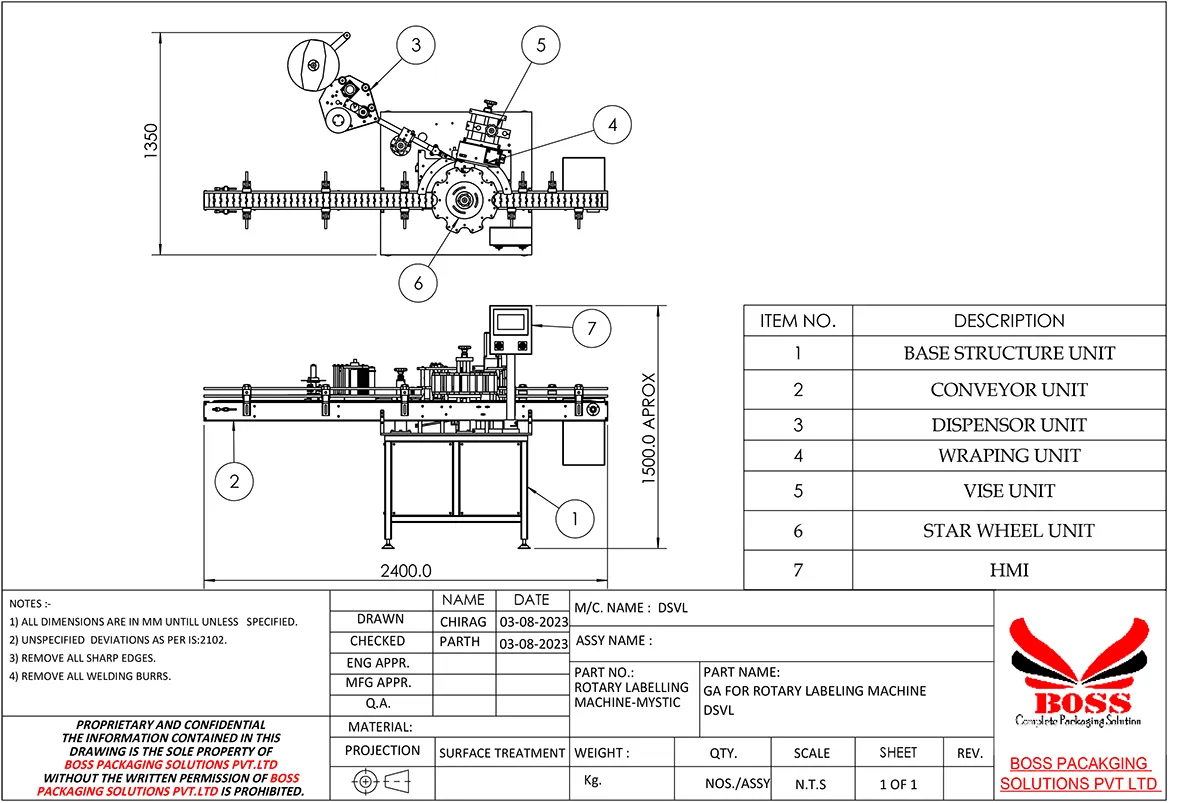

Glass Bottle Sticker Labeling Machine

The Automatic Vertical Sticker Labeling Machine is one of the most users friendly high speed labelling machine with help of star plate. The machine is used for full/partial wrap around Labeling on different size of round containers with help of change parts.

Operation

The round containers positioned on conveyor are passing through timing screw which separate bottles and generate gap between two bottles, separated bottle will pass to the main start plate for labelling via In-feed star plate. Product sensor will pass signal to label dispenser assembly for releasing a label and wrapping guide will press labels on bottle. Labelling bottle will pass to the next operation via out-feed star plate and conveyor.