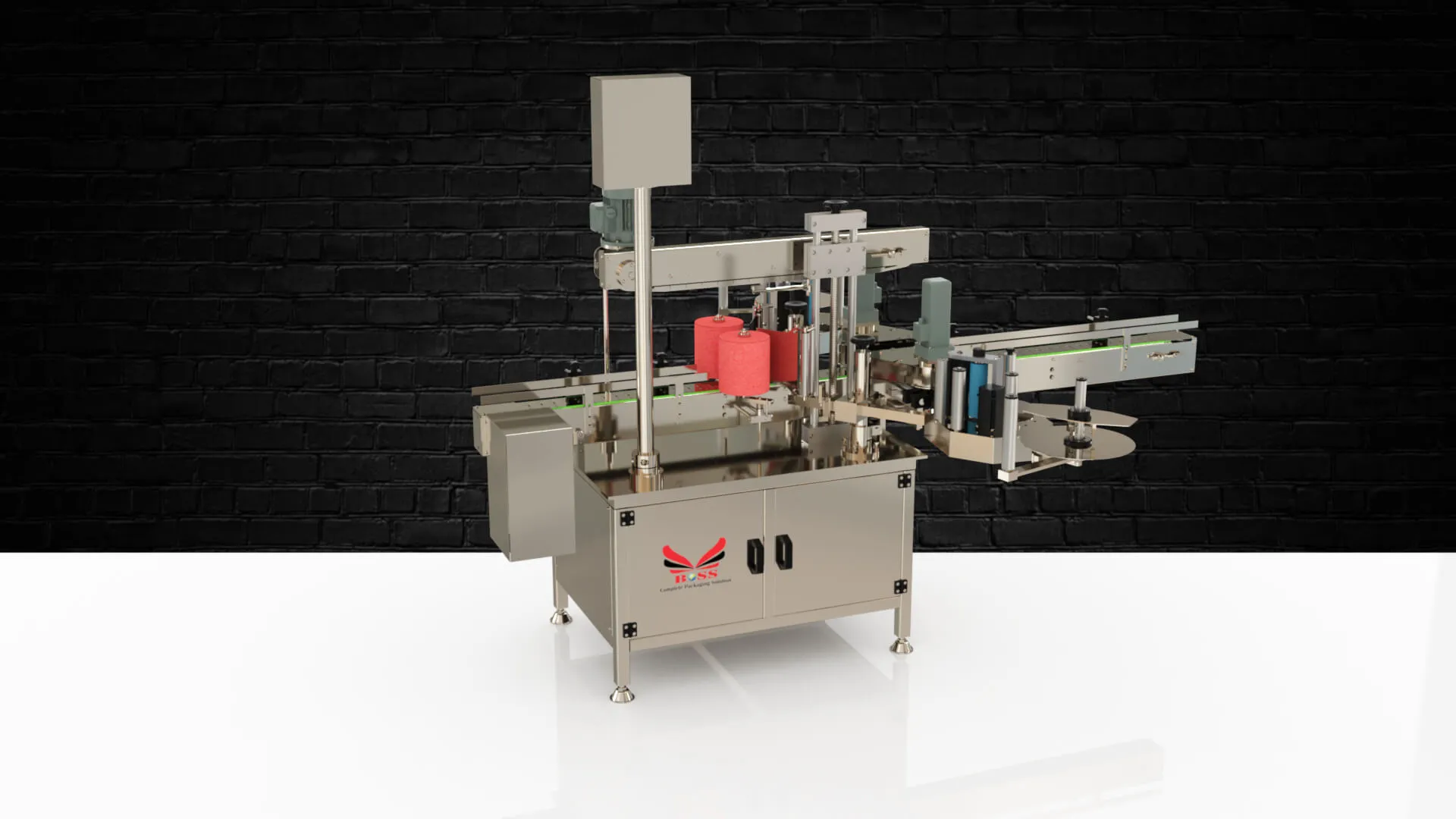

The Automatic Vertical Sticker Labeling Machine is one of the most users friendly. The machine is used for full/partial Labeling on different size of flat or rectangular containers. The automatic model is equipped with roller spacing device resulting in a simple operation with “No change parts required”.

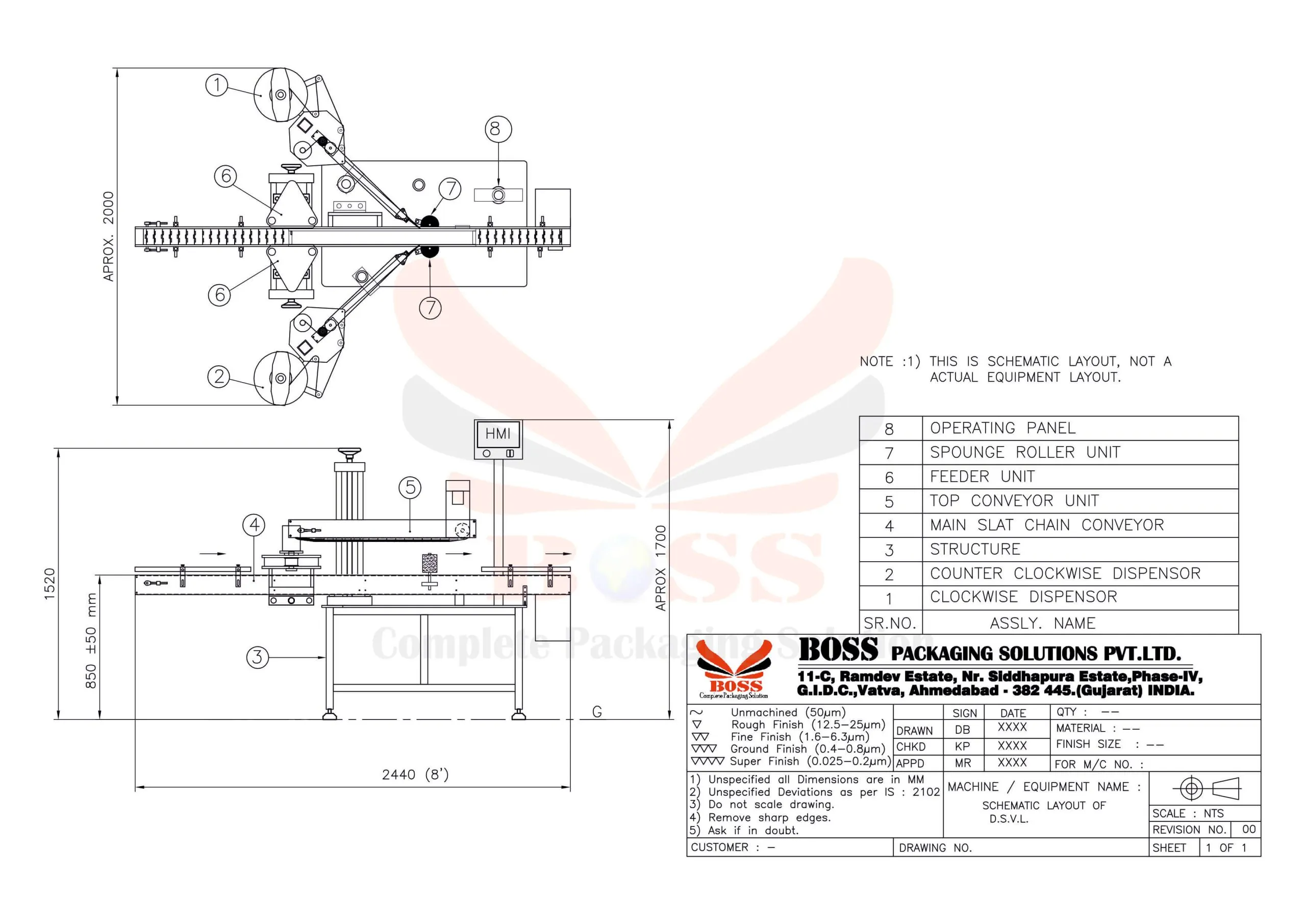

Operation

The filled and sealed bottle is conveyed from the Conveyor and on the same conveyor one bottle separator attachment is provide to separate the bottle from continuous movement. A sensor provided to sense the product after sensing the sensor give command to operate steeper or servo motor to release label when one label is stick the gap sensor give command to stop the servo or stepper during releasing of label provision of brush to press the label & remove the air between label & bottle after completion of the cycle one operation of Labeling is finish & conveyor bring the bottle for next operation.