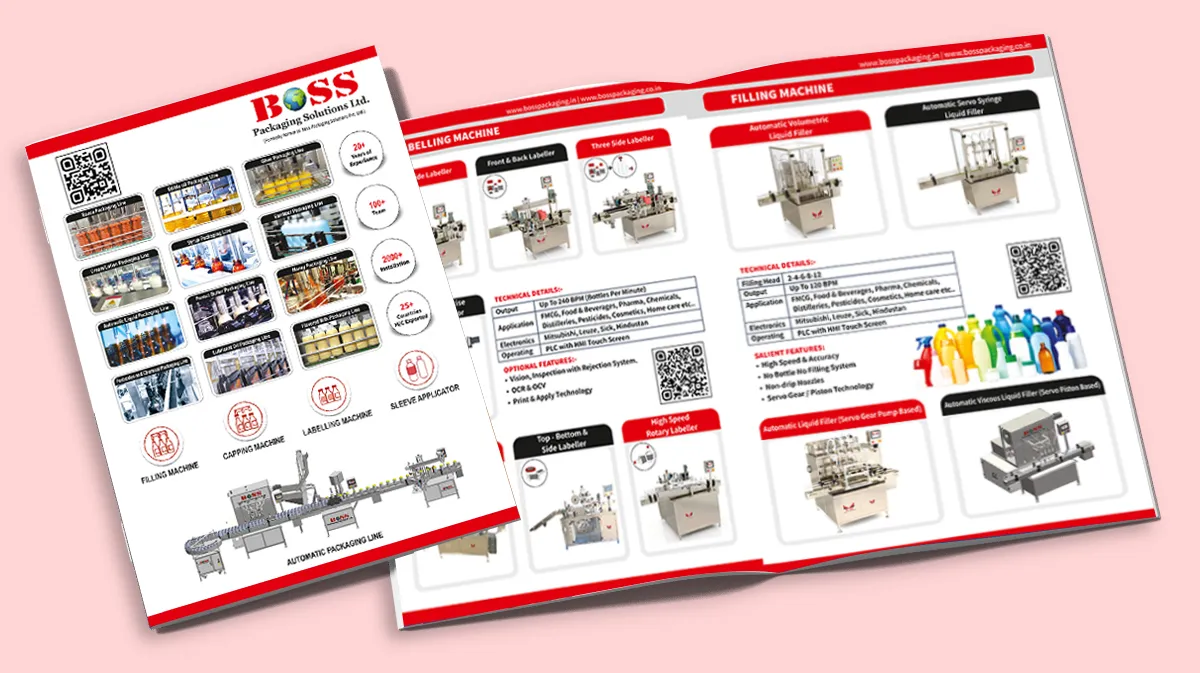

Automatic Gear Pump Filling Machine

Automatic Auger type Powder filling machine is precision built on SS frame completely enclosed in stainless steel sheet and doors are provided to facilitate the servicing of machine. The unit is made compact and versatile in stainless steel elegantly matt finish body.

Operation

The dried, sterilized and siliconised bottles are fed through the infeed Turn Table on the in feed SS conveyor belt at the required speed for feeding. When bottle reaches under the filling head, it is held by the pneumatic bottle holder. Immediately it is be sensed by the bottle sensor and gives signals to magnetic clutch to start to rotate which is mounted on auger shaft. It will fill the desired amount of powder to the bottle through auger, where rotation time is set in the Timer. After filling of first bottle pneumatic bottle holder releases the first bottle to move on conveyor for next operation.