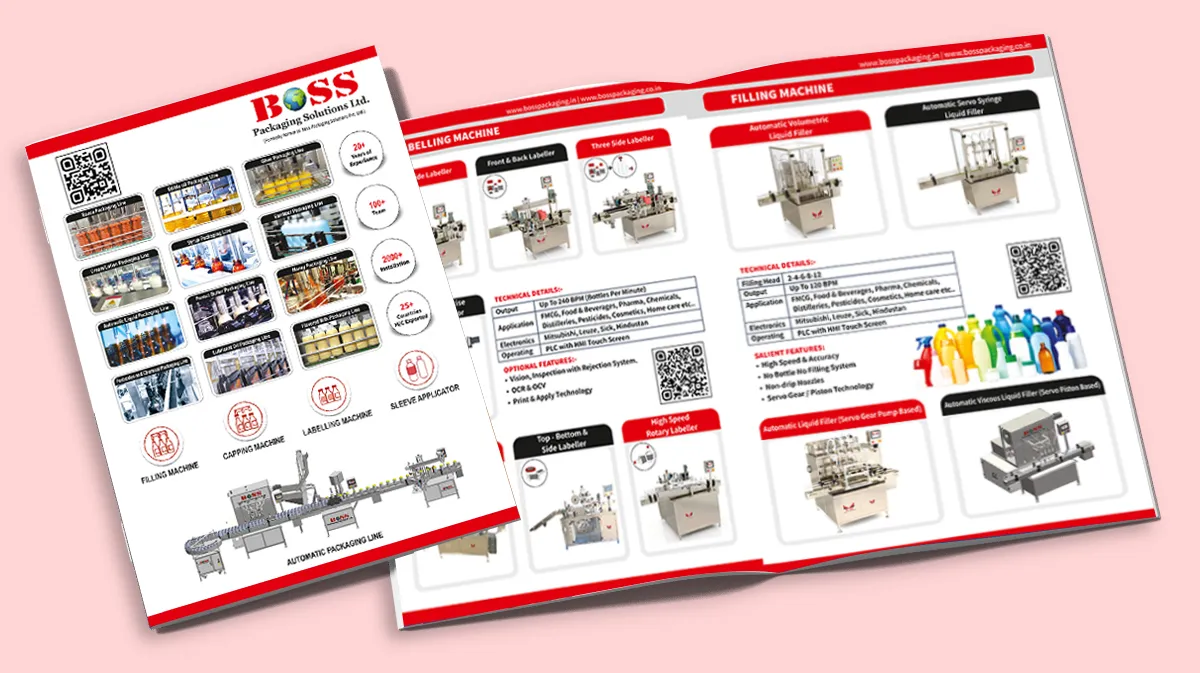

Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard features of the machine.The main drive of the machine and conveyor drive consist of A/c Motor with synchronized variable A/c Frequency Drive.

Automatic multi head linear volumetric liquid filling machines. Leveraging on our in-house production unit, the offered machine is manufactured with the latest technology-digital electronic frequency AC drives. At our manufacturing unit, our engineers have designed the machine adhering to international industry standards and use heavy materials for the machines’ construction. Besides, we offer the most competitive prices in the industry All the machines are GMP models and our preliminary aim is customer satisfaction.