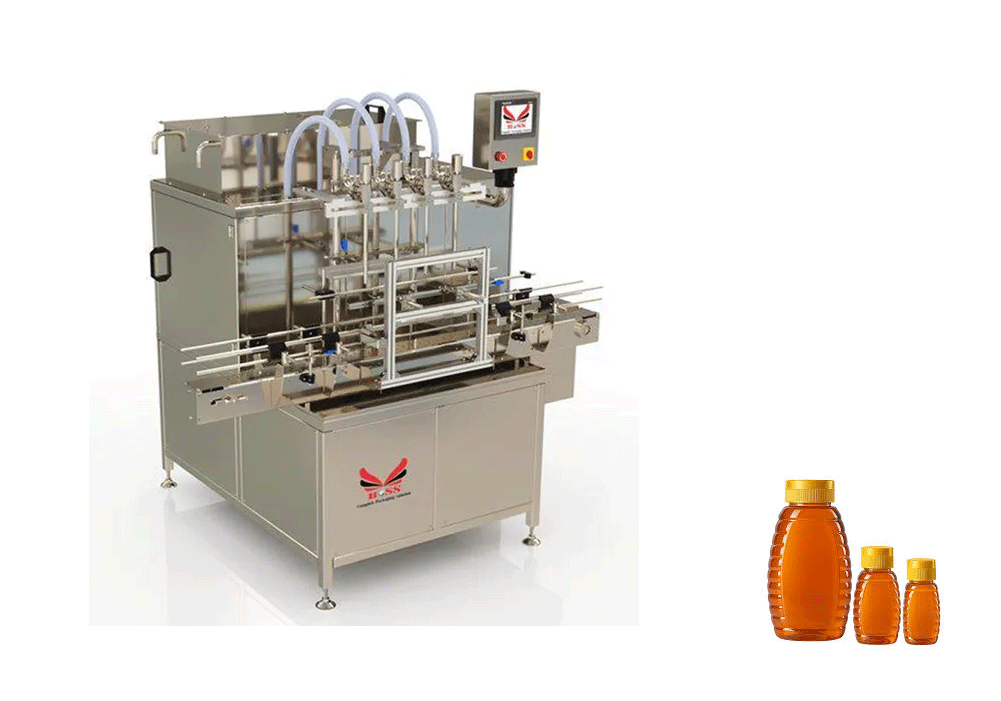

We are a leading automatic honey filling machine manufacturer, offering advanced, hygienic, and highly efficient filling solutions for the food and beverage industry. Our machines are specially designed to handle the thick and sticky nature of honey while ensuring accurate filling, minimal product wastage, and consistent output.

With a strong focus on automation, quality, and performance, our automatic honey filling machines are ideal for honey processors, beekeeping units, food brands, and contract packers.