Shrink Sleeve Applicator Machine for Bottles

Steam shrink tunnels specifically for the application of heat shrinkable sleeve labels and tamper evident bands. Steam shrink tunnels allow for highly uniform heat transfers which are superior when compared to hot air systems. Steam-based machinery provides high precision registration capabilities ,better shape forming and particularly well suited for full body shrink labels. This means that the sleeves will fit tighter and more evenly and the graphics and aesthetics will look better on the sleeves resulting in better shelf appeal

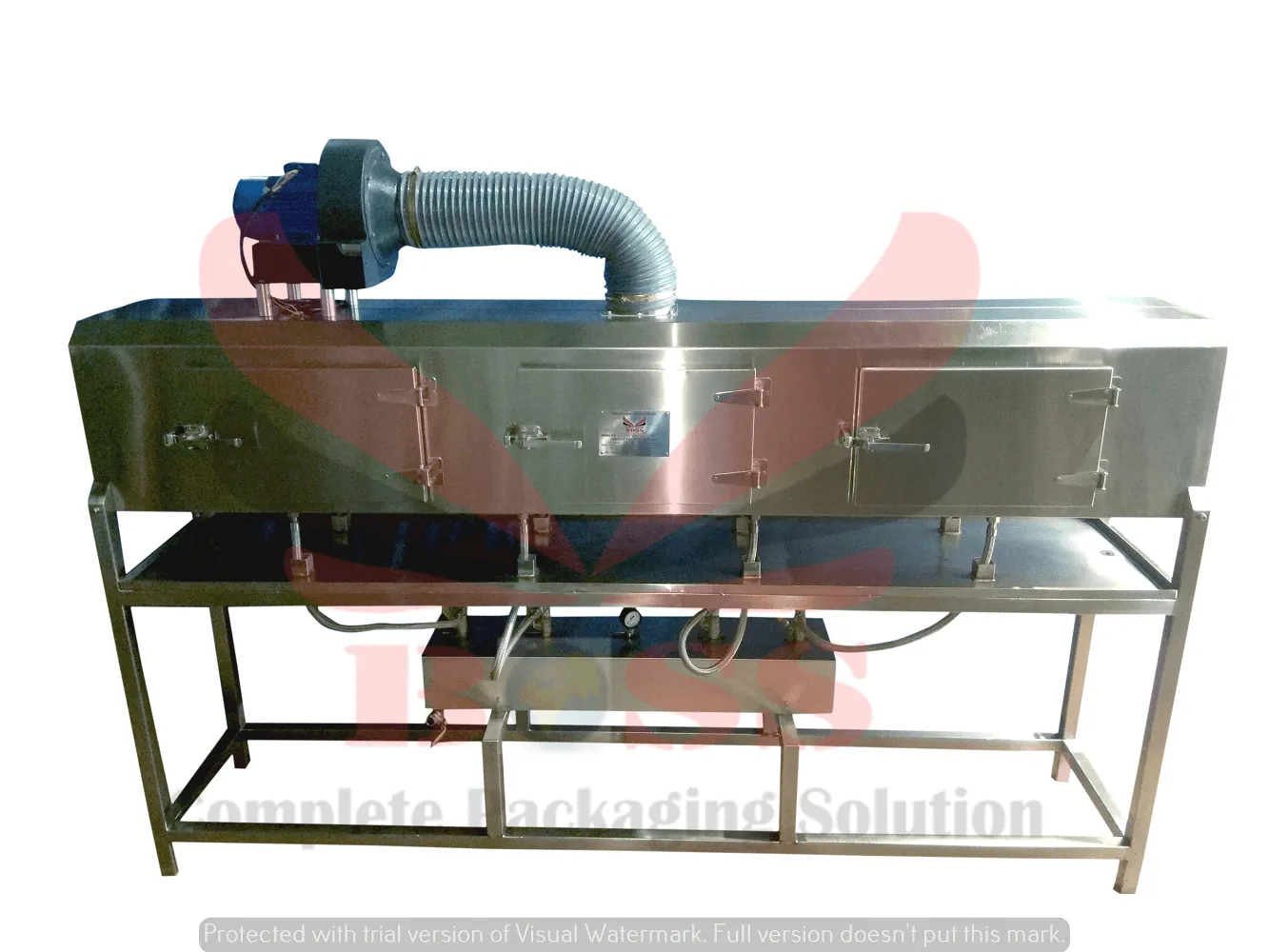

This steam operated tunnel is made up of heavy gauge stainless steel with dual wall construction.. It is delivered with removal hoods, a hinged lid and a drain tray with top opening access for cleaning of products.

Steam shrink tunnels are specially made to run on product lines in which quality and high-end graphics are favored. If your products require spot on registration, brilliant colors, perfect fonts and long term consistency, steam shrink tunnels are for you.