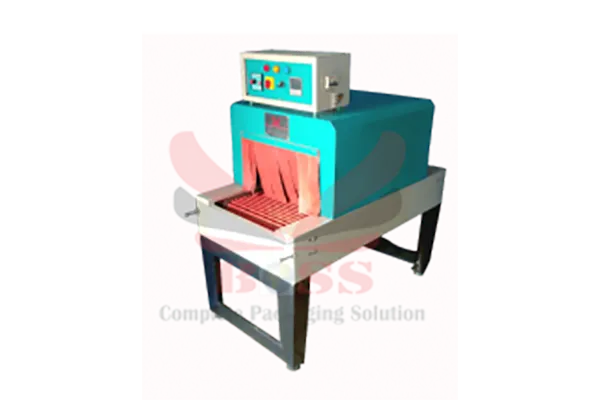

Automatic Shrink Sleeve Machine Manufacturer

Automatic Electric Heat Shrink Tunnel is used to shrink sleeve label on body of round plastic container. These machines work with variety of sleeve label made from PVC, PP, PETG and OPS films. Machine is made of SS 304 make Slat conveyor for feeding of the container. Speed of the Conveyor can be varied through provided speed port on the operating panel. Sleeve label has to be placed manually on plastic container and together they need to put on the conveyor. containers enter in tunnel which has sets of Pin heater which heat the air inside the tunnel and additionally, shrink tunnel contain two blower assembly. Blower is use to facilitate the forced convection type of heat transfer and due to that heated air get circulated inside the tunnel and which give uniform heated air around the travelling container inside the tunnel and thus, assure the label get shrink / sticked perfectly on body of container.