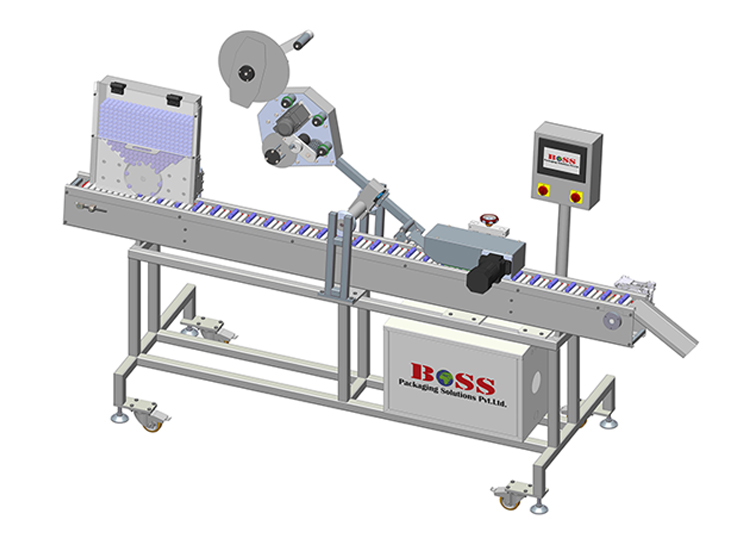

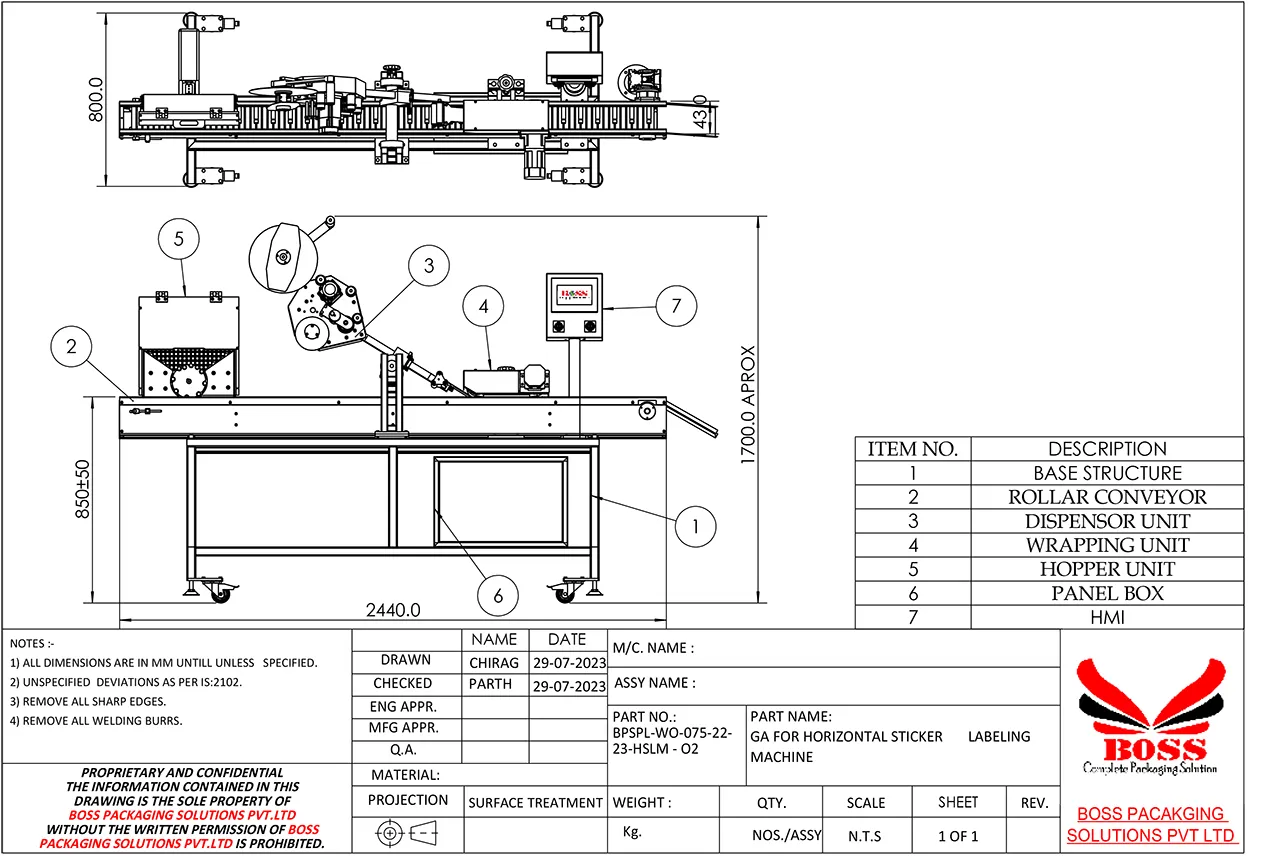

Sticker Lebelling Machine

The ampoule sticker labelling equipment is available with a touch-screen HMI and features a PLC-based system. It is appropriate for overlap labelling, complete and partial wrap-around. Additionally, the ampoule sticker labeller offers an incredible output of 150 every minute. And its horizontal compressed shape makes it a space-saving option.

This is an advanced equipment of ampoule labeller performing its operations even on a small tube or eye drop bottle. A high-end version of the ampoule labelling machine could include speed control. The very fundamental of this ampoule sticker labelling machine is that an in-feed is done on the hopper and through a wire mesh conveyor. Ampoules are loaded onto the hopper of the machine and it is delivered right to the feed worm. The feed worm rotates the ampoule and transfers it to the star wheel. The star wheel then transfers ampoules to the labelling station where the ampoule picks up the label and moves towards the pressing unit. The rotary ampoule sticker labelling machine then gets collected onto an out-feed collection tray additionally this sticker labelling Machine is GMP Model.