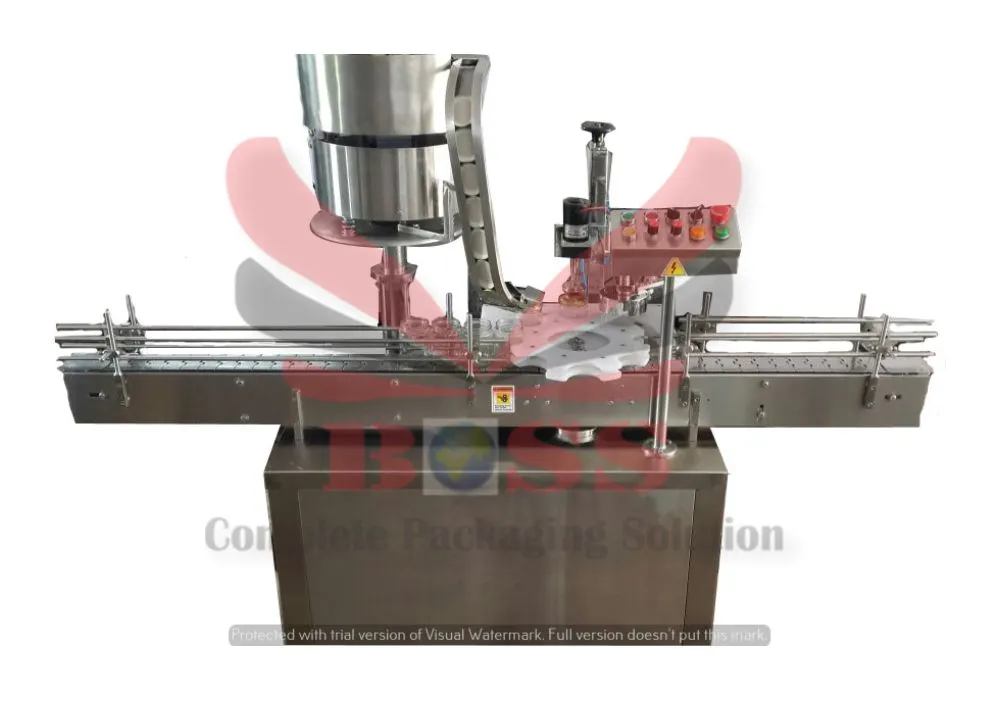

Edible Oil Filling Machine

Boss Packaging Solutions was founded in 2008 and is a well-known manufacturer of a wide range of Cooking Oil Filling Machine manufacturer, supplier, and exporter of Edible Oil Filling Machine in India, we make high-quality Filling Machines for Automatic Liquid Bottle Filling Line, Suace Filling Machine, Automatic Chemical Filling Machine,cotton seed Oil Container Filling Machine, fully automatic filling machine, Gear Oil Filling Machine, Lubricant Oil Filling Machine, Mustard, Mustered oil filling machine, Oil, Refined, Servo Filling Machine, vegetable oil filling machine, Weight Metric Oil Filling Machine application. We offer comparatively lowest price & excellent after-sales service across the globe.

automating the filling process, these machines enhance production capacity, ensure product consistency, and maintain high hygiene standards. Whether for large-scale manufacturing plants, medium-sized enterprises, or small-scale producers, there is an edible oil filling machine designed to meet the specific needs of the operation. Investing in a quality edible oil filling machine not only boosts productivity but also contributes to maintaining the quality and safety of the product, ultimately leading to greater customer satisfaction and business success.