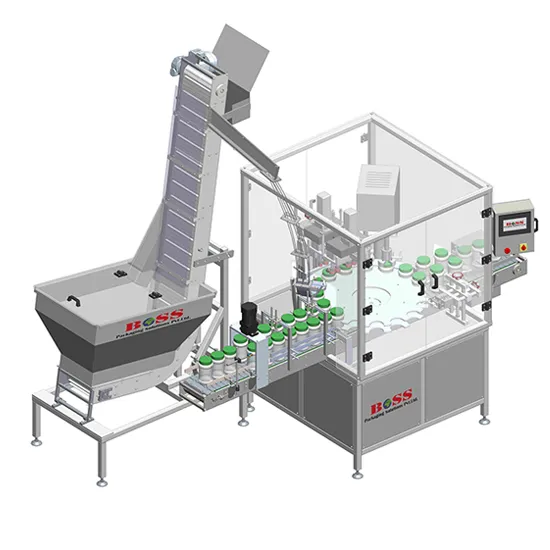

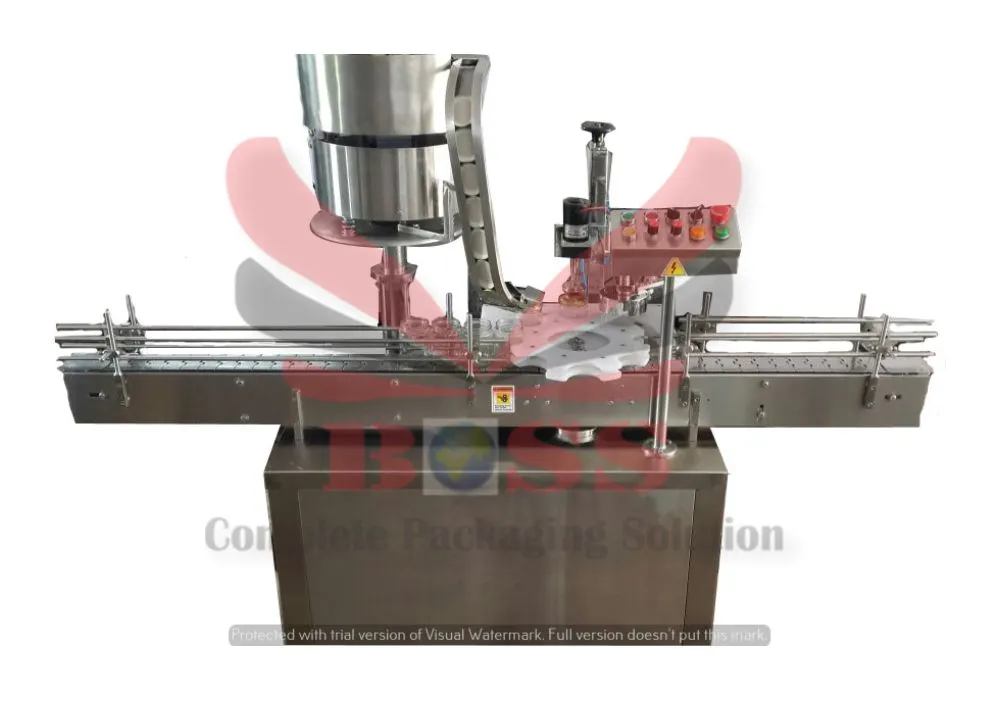

Cap Sealing Machine Manufacturer

Boss Packaging Solutions was founded in 2008 and is a well-known manufacturer of a wide range of Automatic Cap Sealing Machine, including bottle capping machines,Round Bottle Sticker Labelling machines, and liquid filling machines. The oil, automotive, food product, pharmaceutical, and chemical industries have high demand for our goods because of their durable design, extended lifespan, functional fluency, reliable performance, resistance to corrosion, and effective functioning. Furthermore, we are well known for our well curated assortment and personalized packaging.

We have an amazing infrastructural facility with a variety of equipment and machines that are powered by the newest and most advanced technologies. These devices not only make production easier for us, but they also offer excellent assistance with storing the entire series in the right way. Additionally, our experts guarantee that every client need is met on schedule and in accordance with their requests. Thanks to the consistent efforts and unwavering resolve of our staff, we are building a substantial clientele in Ahmedabad, Gujarat.